Designed to transform your manufacturing processes, our suite of AI services brings precision, agility, and intelligence to the forefront of your operations. Discover how leveraging AI can revolutionize your production line, optimize workflows, and drive sustainable growth in an increasingly competitive manufacturing landscape.

These are our comprehensive AI services tailored for manufacturing excellence, created to optimize operations, ensure security, streamline processes, and foster unprecedented growth in the manufacturing sector.

Employ machine learning algorithms to automate quality control, leveraging the power of AI in manufacturing for efficient identification of defects and deviations from product standards.

Develop AI systems enabling customization in manufacturing, fostering flexibility in product design and swift adaptation to market changes through the use of AI in manufacturing.

Integrate AI with robotics for automated execution of complex or hazardous tasks, improving safety and efficiency within the manufacturing process with the use of AI in manufacturing.

Develop AI systems enabling customization in manufacturing, fostering flexibility in product design and swift adaptation to market changes through the use of AI in manufacturing.

Provide real-time monitoring solutions using AI to analyze manufacturing floor data, facilitating immediate decision-making and process adjustments by applying AI solutions for manufacturing companies.

Employ AI systems for comprehensive product lifecycle management, from design to disposal, ensuring optimal resource utilization and sustainability by incorporating AI in manufacturing.

Provide custom AI/ML solution development tailored to the unique needs of manufacturing companies, specializing in the application of AI in manufacturing processes and operations.

Develop AI solutions for efficient warehouse management, including automated sorting, tracking, and retrieval of products, enhancing overall productivity in manufacturing with AI solutions.

Provide real-time monitoring solutions using AI to analyze manufacturing floor data, facilitating immediate decision-making and process adjustments with the application of AI solutions for manufacturing companies.

Streamline operations, reduce costs, and achieve manufacturing excellence.

The global Artificial Intelligence In Manufacturing market is expected to reach at USD 20.8 Billion in 2028 with a CAGR of 45.6% from 2022-2028. Artificial Intelligence (AI) has emerged as a transformative technology in various industries, including manufacturing.

In manufacturing, AI refers to using advanced algorithms and machine learning techniques to automate processes, improve efficiency, and enhance decision-making. AI in manufacturing encompasses various applications, such as predictive maintenance, quality control, supply chain optimization, and robotics integration.

AI, as a transformative force, has redefined manufacturing methodologies. It involves deploying advanced algorithms and machine learning techniques to automate processes, enhance efficiency, and elevate decision-making capabilities. The versatility of AI in manufacturing is evident through its multifaceted applications, including predictive maintenance, quality control, supply chain optimization, and robotics integration.

Leveraging AI solutions for manufacturing companies can improve productivity, reduce costs, and enhance product quality. AI-powered systems can also detect patterns and anomalies in data, enabling proactive maintenance and minimizing downtime.

Adopting Artificial Intelligence (AI) in manufacturing isn’t just a technological leap; it’s a strategic move that brings many benefits, transforming the production landscape. Let’s delve into the advantages of integrating AI solutions for manufacturing companies:

Here are some of the key AI technologies in manufacturing that businesses should keep a close watch on:

Quality control is critical to manufacturing, ensuring that products meet the required standards and specifications. AI has revolutionized quality control by enabling automated defect detection and analysis.

AI-powered computer vision systems can analyze images or videos of products in real-time, detecting defects, anomalies, or deviations from the desired specifications. These systems use machine learning algorithms to learn from a large dataset of defect-free and defective products, enabling them to identify and classify defects accurately.

The advantages of using AI for quality control are numerous.

Selecting the right AI solutions for manufacturing processes requires careful consideration of various factors. Here are some key considerations:

1. Identify pain points: Start by identifying your specific challenges or pain points. manufacturing processes that AI could address. This could include quality control, predictive maintenance, or supply chain optimization.

2. Assess data availability and quality: AI relies on data for training and decision-making. Evaluate the availability and quality of data relevant to the selected AI application. Ensure you can access sufficient and reliable data to train AI models effectively.

3. Evaluate scalability and integration: Consider the scalability of the AI solution and its compatibility with existing systems and infrastructure. Ensure the solution can handle increasing data volumes and integrate seamlessly with other manufacturing systems.

4. Consider implementation complexity: Assess the complexity and resources required for implementing the AI solution. Consider data collection, model training, deployment, and ongoing maintenance.

5. Evaluate vendor expertise and support: Assess AI solution vendors’ expertise and track record. Look for vendors with experience in the manufacturing industry and a proven track record of successful implementations. Consider the level of support and training provided by the vendor.

6. Cost-benefit analysis: Conduct a cost-benefit analysis to evaluate the potential return on investment (ROI) of implementing the AI solution. Consider factors such as cost savings, productivity improvements, and quality enhancements.

By considering these factors, manufacturers can select the right AI solutions that align with their needs and goals.

Implementing AI in manufacturing involves significant investments in technology, infrastructure, and human resources. Therefore, conducting a return on investment (ROI) analysis is crucial to assess AI implementation’s financial viability and potential benefits.

To conduct an ROI analysis for AI implementation in manufacturing, consider the following steps:

1. Identify key performance indicators (KPIs): Determine the KPIs relevant to your manufacturing processes and can be impacted by AI implementation. These could include metrics such as productivity, cost savings, quality improvements, or reduced downtime.

2. Establish baseline metrics: Measure the current performance of the selected KPIs before implementing AI. This will serve as a baseline for comparison and help quantify the impact of AI implementation.

3. Estimate implementation costs: Determine the costs associated with AI implementation, including hardware, software, training, and any additional resources required. Consider both upfront costs and ongoing maintenance costs.

4. Quantify potential benefits: Estimate the potential benefits that can be achieved through AI implementation. This could include increased productivity, reduced costs, improved quality, or enhanced decision-making. To quantify these benefits, use historical data, industry benchmarks, or expert opinions.

5. Calculate ROI: Calculate the ROI by comparing the estimated benefits with the implementation costs. Divide the net benefits by the implementation costs and express the result as a percentage.

6. Consider intangible benefits: Besides financial benefits, consider intangible benefits such as improved customer satisfaction, enhanced brand reputation, or increased employee morale. While these benefits may be challenging to quantify, they contribute to the overall value of AI implementation.

Successful AI adoption requires careful planning, execution, and ongoing management. Here are some best practices to ensure a successful AI adoption:

1. Define clear objectives: Clearly define the objectives and goals of AI adoption. Identify the specific problems or challenges AI must address and establish measurable targets.

2. Start with pilot projects: Begin with small-scale pilot projects to test and validate the effectiveness of AI solutions. This allows for iterative improvements and reduces the risks associated with large-scale deployments.

3. Involve cross-functional teams: Establish cross-functional teams comprising experts from various departments, including operations, IT, data science, and engineering. This ensures a holistic approach and facilitates collaboration and knowledge sharing.

4. Invest in data infrastructure: Ensure you have a robust data infrastructure to collect, store, and process the data required for AI applications. This includes data collection systems, data storage, and data integration capabilities.

5. Focus on data quality: Data quality is crucial for the success of AI applications. Invest in data cleansing, normalization, and validation processes to ensure the accuracy and reliability of the data used for training AI models.

6. Provide training and upskilling: Provide training and upskilling programs to equip employees with the necessary skills to work with AI technologies. This includes training in data analysis, machine learning, and AI model deployment.

7. Monitor and evaluate performance: Continuously monitor and evaluate the performance of AI applications. Collect user feedback, measure key performance indicators, and make iterative improvements based on the insights gained.

8. Ensure ethical and responsible AI use: Consider ethical implications and potential biases associated with AI applications. Ensure that AI systems are transparent, explainable, and comply with relevant regulations and standards.

Here are some of the challenges and considerations in AI manufacturing that businesses should take into account

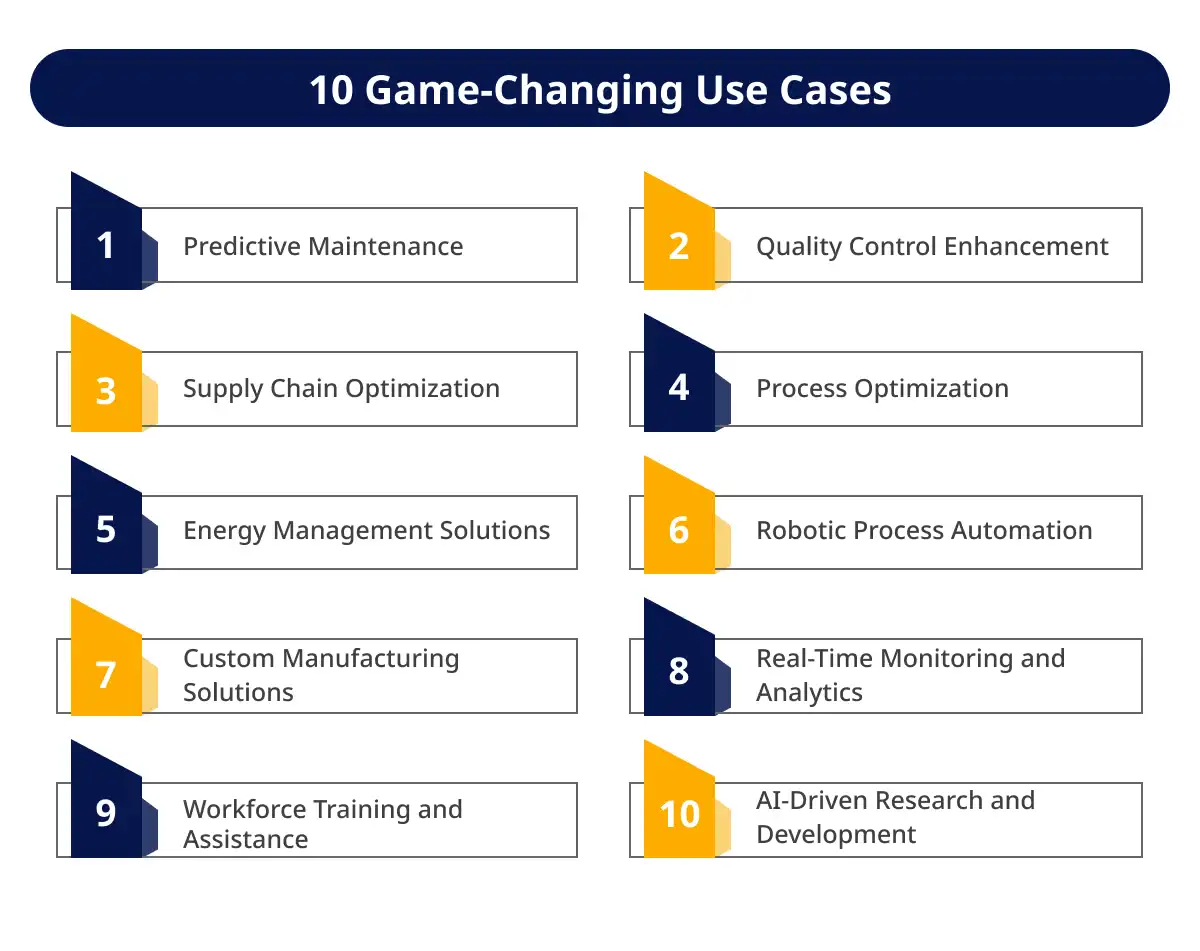

In the dynamic manufacturing landscape, the integration of Artificial Intelligence (AI) and Machine Learning (ML) introduces transformative use cases, optimizing processes and elevating operational efficiency. Here are ten compelling applications of AI/ML in manufacturing:

In essence, these AI/ML use cases redefine the manufacturing landscape, offering solutions that not only streamline operations but also foster a more responsive, adaptive, and sustainable approach to production.

The future of AI in manufacturing holds immense potential for further advancements and innovations. Some key trends and predictions include:

1. Increased adoption of AI-powered robotics: Robotics and automation will continue to play a significant role in manufacturing. AI integration enables robots to perform complex tasks and adapt to changing environments.

2. Enhanced predictive maintenance capabilities: AI algorithms will become more sophisticated in predicting equipment failures and optimizing maintenance schedules, leading to reduced downtime and improved productivity.

3. Integration of AI with the Internet of Things (IoT): AI and IoT will enable manufacturers to gather real-time data from connected devices and use AI algorithms to analyze and act upon this data, leading to improved operational efficiency and better decision-making.

4. Advancements in computer vision for quality control: AI-powered computer vision systems will become more accurate and efficient in detecting defects and ensuring product quality, reducing the need for manual inspection.

5. AI-driven supply chain optimization: AI algorithms will optimize supply chain processes, including demand forecasting, inventory management, and logistics, improving efficiency and cost savings.

Ans. We have a team of experienced professionals who specialize in AI and understand the unique challenges of the manufacturing sector. Our AI solutions are tailored to meet the specific needs of your manufacturing processes, resulting in improved efficiency and productivity.

Ans. The cost of implementing Artificial Intelligence in Manufacturing can vary depending on factors such as the complexity of your manufacturing processes, the size of your operations, and the specific AI solutions required. We offer customized pricing based on your specific requirements. You can contact our sales team for a detailed quote.

Ans. We provide comprehensive support and maintenance services to ensure the smooth operation of your AI systems. Our support team is available to address any technical issues or questions. We also offer regular updates and upgrades to keep your AI systems up-to-date with the latest advancements.

Ans. You can contact our team to discuss your specific requirements and goals to get started.

Our team will work closely with you to understand your manufacturing processes and identify areas where AI can bring significant improvements. We will develop a customized plan and implementation strategy to integrate AI into your manufacturing operations.

Ans. Yes, AI can help optimize manufacturing processes by analyzing large amounts of data, identifying patterns, and making predictions. AI can automate repetitive tasks, improve quality control, optimize inventory management, and enhance operational efficiency.

Ans. Yes, we prioritize the security of your data and systems. We implement robust security measures to protect your data from unauthorized access or breaches. Our AI solutions are designed to comply with industry standards and regulations to ensure data privacy and security.

We are grateful for our clients’ trust in us, and we take great pride in delivering quality solutions that exceed their expectations. Here is what some of them have to say about us:

Trusted by Startups and Fortune 500 companies

We can handle projects of all complexities.

Startups to Fortune 500, we have worked with all.

Top 1% industry talent to ensure your digital success.

Let's discuss how we can bring your vision to life.